Baking Equipment Built For Your Unique Needs

More Than Customization, It's Your Competitive Edge

Deep Process Understanding

We don't just understand equipment; we have a deep understanding of your baking process, production workflow, and market demands.

Your Technical Expert Partner

We are more than just a supplier; we are the technical experts by your side, leveraging extensive experience to provide precise custom solutions.

Driving Your Business Success

Our goal is to help you improve production efficiency, strengthen your brand value, and ultimately, gain a competitive edge.

Customization Solutions

Independent Bakers & Small Bakery Brands

- ✔

Infinite Creativity in a Limited Space

Limited space? We can flexibly adjust equipment dimensions to perfectly fit into your kitchen layout. Pursuing a unique baking process? We can customize temperature control systems and heating modes to satisfy your ultimate quest for the perfect taste and texture. We help you create a powerful bakery that showcases your brand's personality, all within your space constraints.

Entrepreneurs of Equipment Brands

- ✔

From Brand Concept to Market-Leading Product

As a brand owner, you need a unique product to stand out from the competition. We provide deep customization services—from colors and logos to core functions—to help you build a differentiated product with a true competitive edge. More importantly, we support a 1-unit MOQ. This drastically reduces your trial-and-error costs, empowering a fast and agile brand launch.

Bakery Equipment Distributor

- ✔

Win More High-End Clients with the Power of Customization

In a competitive market, offering custom solutions is your key to standing out. Partner with us, and you'll have the ability to meet any end-customer's special requirements, confidently serving high-value clients like large bakery chains and central kitchens. This not only boosts your profit margins but also solidifies your market position as a professional solution provider.

What to Consider Before Customizing?

You Understand Baking, But Not Engineering Parameters

The biggest challenge is accurately translating your production pain points and business goals into an executable technical plan for the factory, without any misinterpretation.

Custom Equipment Requires Custom Parts

Custom ovens often require special components like high-precision sensors or heating elements. If the supply chain is poorly managed, you risk project delays and unexpected cost increases.

Why Does Customization Cost More

Because customization involves additional R&D, molds, and small-batch manufacturing, the unit cost is naturally higher than for standard products. Finding the perfect balance between a unique design and a manageable budget is a major challenge.

Most Factories Don't Welcome Small Orders

Because they aren't set up for custom work, most manufacturers have extremely high Minimum Order Quantity (MOQ) requirements. This becomes the biggest barrier for new projects or small-scale testing.

Our Customization Capabilities

Seamless Integration Into Your Space & Workflow

Whether you need a countertop oven for a compact kitchen or a specific height to match your production line, we can flexibly adjust the equipment's dimensions for a perfect fit into your work environment.

Core Functions Built For Your Unique Process

We can customize precise temperature profiles or integrate automated programs for one-touch production. We break the limits of standard equipment to perfectly match the performance to your product's needs.

Make Your Equipment Part of Your Brand Identity

We offer comprehensive appearance customization—from exclusive colors and unique materials to integrated brand LOGOs—to strengthen your professional, unified brand image and turn your equipment into a brand ambassador.

Perfect Your Production Flow with Custom Accessories

We can design and integrate custom accessories like special-shaped baking pans, integrated proofing systems, or dedicated conveyor belts to help you create a seamless and efficient production loop.

The Complete Process from Concept to Delivery

Initial Consultation & Proposal

You share your concept with us—including function, capacity, size, and application scenarios. Our expert team will discuss technical feasibility and cost estimates with you to provide a professional preliminary solution.

Detail Confirmation & Formal Plan

Our engineers will create a detailed design plan for you. We will communicate and finalize all customization details with you, and only move to the next step once you are completely satisfied with the plan.

Prototyping & Your Approval

We will quickly build a functional prototype and conduct rigorous performance and safety tests. The key is, you personally confirm the sample and provide feedback for adjustments. We will not proceed without your approval.

Precision Manufacturing & Strict Quality Control

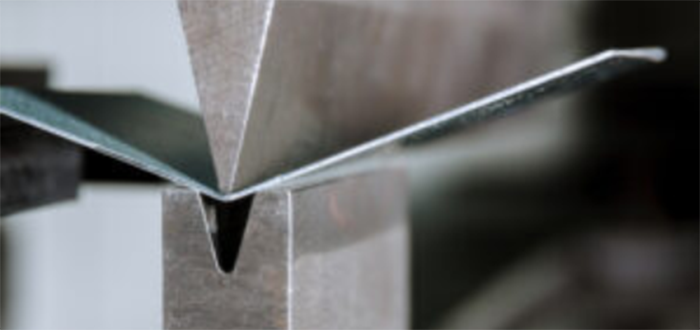

We use precision cutting, welding, and other processes to accurately bring the confirmed design to life. Before leaving our facility, every single unit must pass our rigorous quality inspection to ensure its safety, durability, and temperature control stability.

Secure Packaging & Global Delivery

We use professional, shock-proof, and moisture-proof packaging to ensure your custom equipment is safe and sound during transit. We offer multiple logistics options to deliver the equipment safely to your designated location.

Delivery Support & Long-Term Partnership

Delivery isn't the end; it's the beginning of our long-term partnership. We provide clear installation guides and manuals, plus a 24-hour after-sales team to quickly respond to your maintenance and parts needs, ensuring your equipment always remains a reliable productive asset.

SamBake Core Advantages

Deep Expertise, Precise Understanding of Your Needs

With our founder's 20 years of industry R&D experience, our team can accurately translate your pain points into technical solutions.

Extensive Customization Experience

With 90% of our orders being custom, our experience is vast. Whether you're a large baking factory or a boutique shop, we provide expert support.

Efficient Supply Chain & Stable Delivery

We've established a complete supply chain covering everything from raw material procurement to parts production. This ensures efficient delivery of custom orders and guarantees long-term, stable supply to help you expand your market.

Low MOQ Requirement

Starts from just 1 unit, offering truly "no-threshold" customization.

Advanced Production Equipment

We utilize Swiss-imported laser cutting machines and Italian-imported bending centers for high-precision manufacturing. This guarantees the quality standard of every device and ensures each custom detail is perfectly executed.

How can I help You?

- *Name

- *Title

- *Content

- Name:

- Vickey

- Tel:

+86-18862554041

- Email:

- sales@sambake.com

- Address:

- Xinxiang Industrial Park,Wuxi City,Jiangsu China