Bakery Equipment Industry Outlook 2026: Market Trends, Automation, and Custom Solutions

Welcoming the New Year Together

As we welcome the New Year, SamBake extends warm greetings to our global partners, clients, and friends. The coming year represents both reflection and aspiration — a moment to consider the evolving landscape of the bakery industry and how commercial bakery equipment continues to play a role in shaping production practices around the world.

Global Bakery Equipment Market: Growth and Trends

The global bakery equipment market continues to show steady growth. According to market research, the global bakery equipment market was valued at approximately USD 10.5 billion in 2023 and is projected to grow to around USD 18.3 billion by 2032, at a compound annual growth rate (CAGR) of about 6.1%. This growth is driven by increasing demand for a wide range of baked goods, technological advancements, and the expanding global foodservice sector.

North America remains a strong regional market due to established food processing industries and demand for advanced equipment. Meanwhile, the Asia Pacific region, including China, is expected to witness rapid growth in equipment demand due to urbanization and rising consumer spending on convenience and premium bakery products.

Bakery Processing Equipment Outlook for 2025-2035

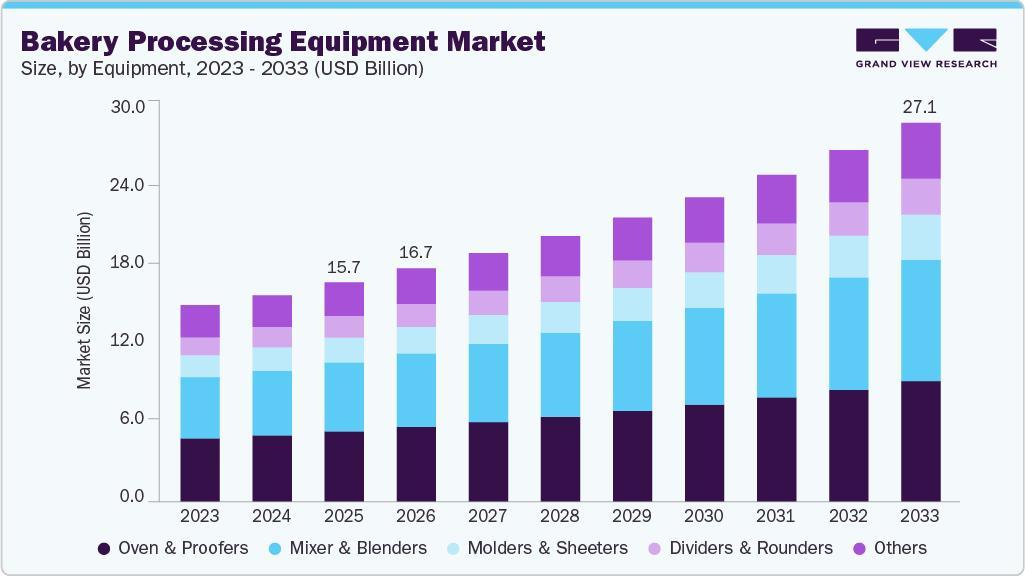

More focused reports specifically on bakery processing equipment show similar momentum. The bakery processing equipment market is estimated to reach around USD 15.7 billion in 2025 and could grow to over USD 27 billion by 2033, with demand fueled by the proliferation of cafés, retail bakeries, and artisanal producers globally.

This growth reflects an increasing need for a wide range of machinery including mixers, ovens, proofers, sheeters, and other automated solutions that help bakeries improve efficiency, consistency, and quality — especially as consumer preferences diversify.

Trends That Matter to Bakery Production

As automation becomes increasingly standard, bakeries of all sizes are investing in equipment that enables consistent output with less labor dependency. Experts suggest automation may no longer be optional as labor shortages and quality consistency pressures increase. Modular and scalable automation systems are becoming more accessible to producers beyond large industrial facilities.

Growing consumer demand for specialty and artisanal bakery products — including healthy, organic, and gluten-free options — also encourages investments in flexible and adaptable equipment capable of handling diverse recipes and formats.

From Industry Trends to Real Equipment Challenges and Needs

Behind broader industry trends lie very practical challenges faced by bakery operators in daily production. Equipment designed for standardized output often struggles to adapt to space limitations, particularly in urban bakeries and restaurant kitchens. Bakers who have worked with multiple oven brands frequently encounter recurring issues such as uneven heat distribution, inefficient workflow design, or maintenance complexity.

At the same time, service and maintenance professionals gain first-hand insight into long-term durability issues and structural weaknesses that are difficult to resolve with off-the-shelf equipment. These experiences reveal a growing gap between standardized machinery and real-world production environments.

As global equipment volumes grow, automation becomes more common, and bakery product lines diversify, this gap directly translates into specific equipment needs. Reliable mixers, energy-efficient ovens, consistent dough handling systems, and scalable production lines are no longer optional upgrades, but essential tools for bakeries striving to balance product quality, operational efficiency, and long-term stability.

Why Customization Is Becoming a Strategic Requirement

As the gap between standardized equipment and real production environments becomes more visible, customization is no longer limited to exterior elements such as color or branding. For many bakery operators, experienced bakers, and even equipment service professionals, the real demand lies deeper — in structure, function, materials, and workflow design.

Bakers who have used multiple ovens over time often develop a clear understanding of recurring technical limitations in the market, from heat control logic to chamber layout and maintenance access. Similarly, companies specializing in equipment repair and maintenance gain long-term insight into which components fail first, which designs increase downtime, and which structural choices affect durability.

In these scenarios, OEM and ODM solutions play a critical role. Instead of adapting production processes to fixed equipment designs,customization allows equipment to be built around actual operating conditions, such as kitchen layout constraints, product-specific baking requirements, energy efficiency targets, and long-term service considerations. This shift reflects a broader industry movement: from purchasing equipment as a commodity to treating it as a production system tailored to real-world use.

Looking Ahead in 2026

Looking forward, the bakery equipment industry is expected to continue its steady expansion alongside the broader growth of the bakery sector. Manufacturers will likely focus on automation integration, energy efficiency, and customization options that support diverse production needs — from artisanal bakeries to larger processing facilities.

SamBake remains committed to observing these trends and working with clients to develop practical, efficient, and tailored equipment solutions that empower bakeries to succeed in an evolving market.

References & Data Sources

DataIntelo — Global Bakery Equipment Market Report

Grand View Research — Bakery Processing Equipment Market

BakeryMachinery.net — Industrial Bakery Technology Outlook